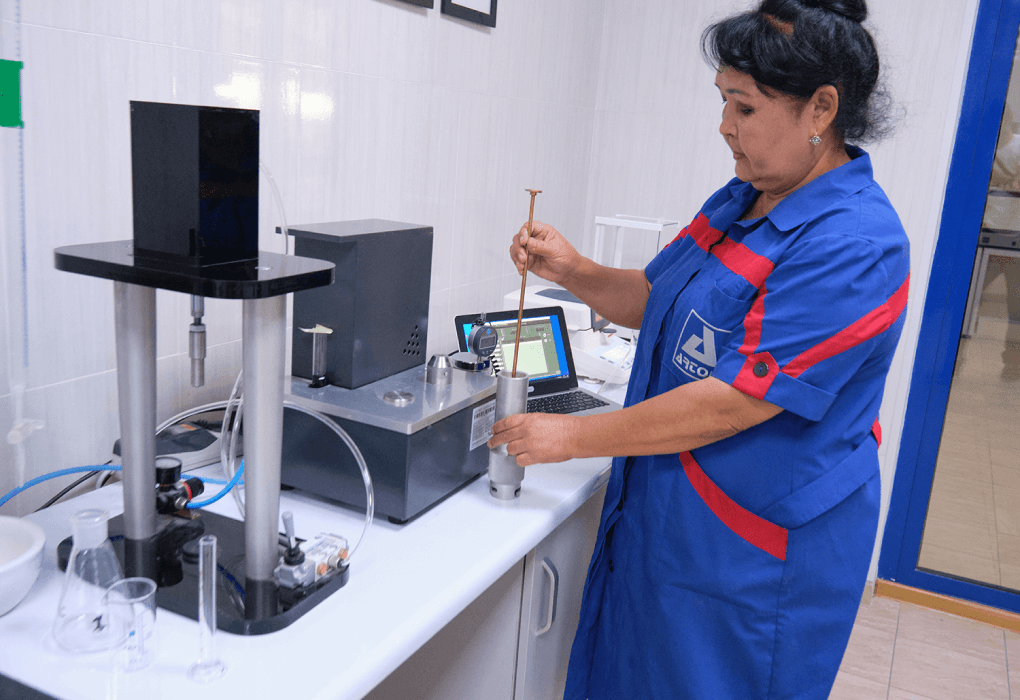

The laboratory of the JV LLC «EAST MINING INVEST» plant is equipped with modern laboratory equipment «MaschinenbauGmbHG», «BINDER GMBH» Germany, «ASZTT Pvt.Ltd» India, «VEKTOR» Turkey. This equipment and qualified laboratory personnel allow for high-quality testing raw materials and monitoring the production of autoclaved aerated blocks 24 hours a day at all stages of the technological process.

The factory laboratory controls incoming raw materials for compliance with all regulatory requirements for the production of an autoclaved aerated block: quartz sand (GOST 8736-93), cement (GOST 10178-76), lime (GOST 9179-77), gas former (aluminum paste (GOST 5494-95), gypsum stone, gypsum anhydrite (GOST 4013-82), water (GOST 23732-79).

After confirming the conformity of the quality of all materials, the head of the laboratory, together with the technologist, adjusts the recipe composition to produce a high-quality gas block.

Laboratory employees control the entire technological process:

- Incoming control of all materials entering the enterprise territory.

- The process of dosing components and temperature conditions during pouring.

- All processes during the period of maturation of massifs and gaining plastic strength.

- Temperature conditions in the pre-autoclave area.

- Final control of each batch of finished products.

All aerated concrete produced by the enterprise is tested for compliance with physical and mechanical indicators: average compressive strength of concrete (kgf/s²), average dry density (kg/m³), frost resistance, thermal conductivity, drying shrinkage, vapor permeability and control of geometric parameters of finished aerated concrete.